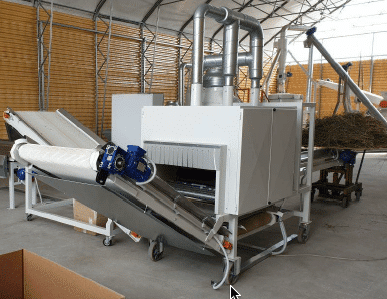

HEMP PROCESSING LINE

Hemp processing line – capacity up to 1000 kg/h

PROCESSING LINE FOR PROCESSING OF INDUSTRIAL HEMP

Description of the processing line:

Processing material (harvested dry industrial hemp) is dosed on the input conveyor of the hemp separating machine. In

the separator the flowers, seeds and leaves are separated from the stem.

After the separation, the stems go out on one output and the mixed mass of separated flowers, seeds and leaves go on another, and are then dosed on the inclined conveyor belt. The inclined conveyor belt is designed for dosing the mixture of flowers, seeds and leaves on the buffer.

The buffer is designed for continuous even dosing of material for processing on a vibrating sieve in order to

separate the rest of the stem material.

Even dosing achieves higher quality processing in daily processes with minimal losses. After the separation of rest of the stem, the mixture of flowers, seeds, leaves and stalk parts are transported via the conveyor belt to the screw conveyor designed for dosing into the rebler.

The rebler is used to crush leaves and flowers to a fraction of 0-3 mm (< 2 mm on average) by pushing material through square outlets and to separate fractions of broken small branches, stem, stalk and seeds through the back output outlet – so called CBD preparation material. Under the sieve there is an output outlet for separated parts of the leaf blade and flowers.

On vibrational sieve mixture is sieved once again in order to separate stalk and small stem parts, and the mixture

of leaf parts and flowers is dosed directly into the bags via screw conveyor for filling the bags.

On the back part of the rebler there is a mixture of seeds, branches and stem output. The mixture is sieved on

vibrational sieve in order to separate the seed material out of the mixture.

As a final step of seed separation, the seed is dosed into the pneumatic separator, in order to separate light weight fraction and get the clean seeds as second output, beside the CBD preparation material.