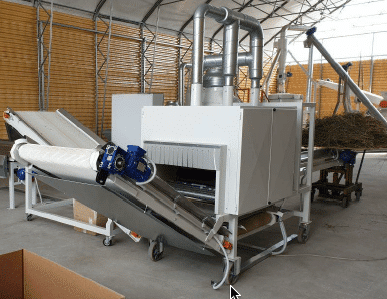

Floor Container Dryer for Industrial Hemp

Floor container dryer is designed for drying of industrial hemp, herbs, grains , pumpkin seeds, vegetables, mushrooms etc.

Dryer HKS -12/60 is produced in 3 sizes with an effective surface area of the floor 24 m², 32 m² or 40 m².

Dryer capacity for the layer of 40 cm, the effective surface area:

– for 24 m² is 9,6 m³

– for 32 m² is 12 m³

– for 40 m² is 16 m³

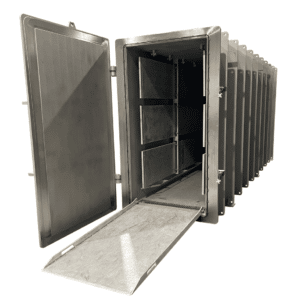

Construction of the dryer is made from galvanized steel pipes, and the walls and roof of thermo-insulating panels 50 mm thick with a polyurethane filling. The dryer is container type and does not need a building permit.

Floor of the dryer is made of perforated galvanized sheet metal thickness of 1.5 mm, Ø 3.2 mm perforations.

The doors are double/two doors, for charging and discharging of processing material.

Dimensions of the dryer:

-Height: 2800 mm

-Width: 4000 mm

Layout of an effective length:

– 6000 mm for the dryer of 24 m²

– 8000 mm for the dryer of 32 m²

– 10000 mm for the dryer of 40 m²

If the dryer is located outdoors, it is necessary to make eaves 2 meters long in length of a drier, for protection of the thermal generator from weather conditions.

FUEL SOURCE:

The dryer can used with heating oil, natural gas and biomass (wood pellets or wood chips) as a fuel source.

1.Thermal generator type HT-AD is designed for heating spaces with warm air.

Energy source: wood chips G20 or pellets

The fuel is put into the input hopper which is 1 m³ of capacity, through which it is transported by a screw conveyor system into the furnace. The dosage is carried out by a dual axial screw transport system with airlock which ensures safety from returning of flame.

Thermal generator furnace is made out of sheet metal and the parts that are exposed to intensive heat are made out of fireproof sheet metal. The furnace is located beneath the fan and there is an integrated temperature regulator on the furnace, which increase the performance while reducing the level of output flue gas temperature.

Thermal generator of power of 10 – 150 kW can be equipped with an axial or radial fan, its capacity is 14,000 to 30,000 m³ of air, electronic thermostat with temperature probe and electrical control cabinet.

The removal of ash is done manually by emptying ash-container. (See photos of the Thermal Generator of Biomass: Wood chips or pellets)

2.Thermal generator type HT-RD is designed for warm air heating spaces and drying of agricultural products.

Energy: dry firewood, length up to 1.1 m in maximum diameter of 20 cm, the maximum humidity content of 20%.

The combustion process: pyrolysis.

Dry firewood is manually put to furnace (reactor) for the gasification of wood.

Thermal generator furnace is made of sheet metal and the parts that are exposed to intense heat are made out of fireproof sheet metal and thermal concrete. The furnace is located beneath the ventilator and there is an integrated temperature regulator on the furnace. That increases the performance while reducing the level of output flue gas temperature.

Thermal generator of power of 50 – 150 kW can be equipped with an axial or radial fan, his capacity is 14,000 to 30,000 m³ of air, electronic thermostat with temperature probe and control electrical cabinets.

The removal of ash is done manually. (See photos of the Thermal Generator on firewood)

Watch video below on the standard floor container dryer (fixed).