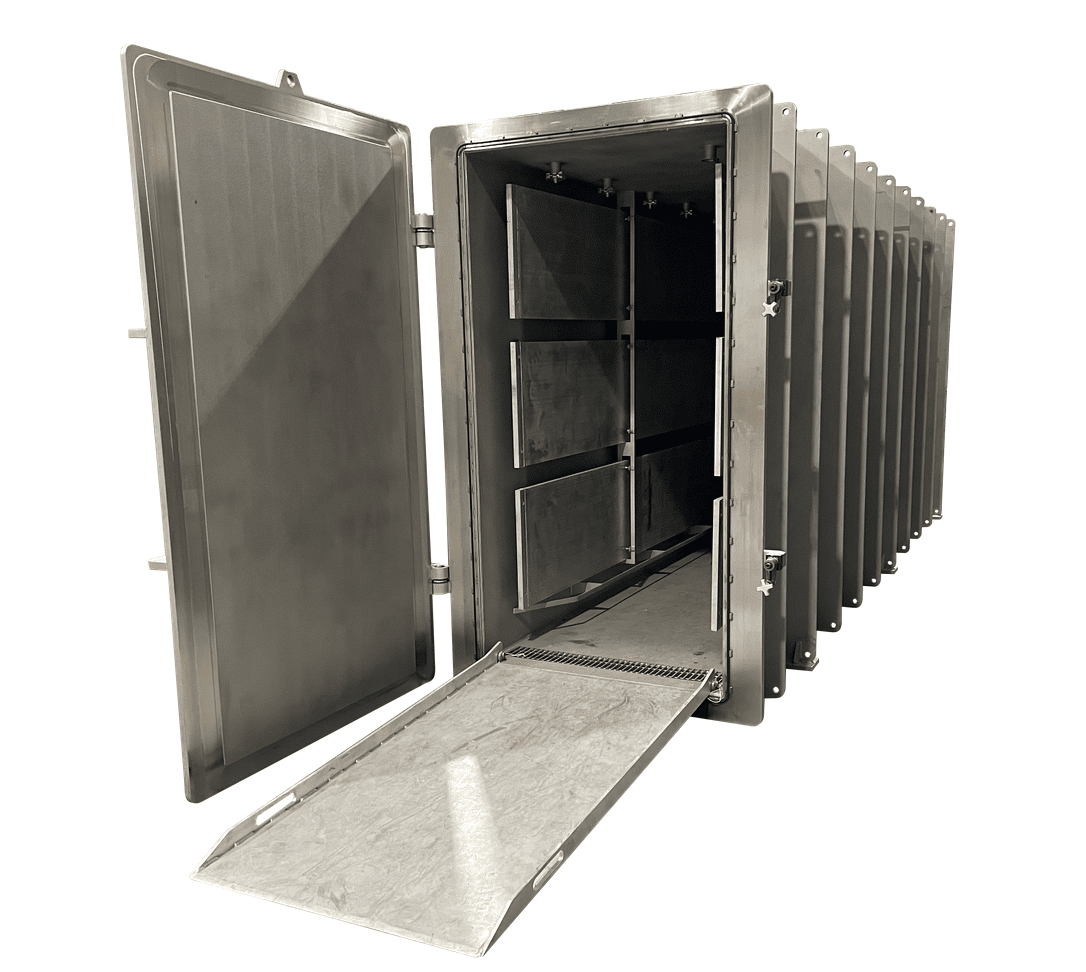

Cryo Cure High-capacity models HC4, HC7, and HC10 Drying Machines

Dry and Cure Cannabis In As Little As 24 Hours

Cryo Cure’s patent-pending technologies and methodologies are to eliminate the human error that can occur during the cannabis curing and drying process. The machines are pre-programmed for low moisture content while preserving the terpenes and trichomes.

WHY CRYO CURE HIGH-CAPACITY MACHINES?

Cryo Cure HC Models are the highest capacity freeze dryers being offered to the cannabis and hemp industry

that also includes our patented and global patent-pending, freeze drying process that gives you perfect product,

every time. Preserves terpenes, optimal moisture content and stabilized water activity.

Cryo Cure understands the impact cycle time has on annual production.

We have designed our systems with:

• External product handling –loading and unloading while the machine is processing another batch

• Quick condenser defrosting.

• Faster processing due to refrigeration capacity – lower chamber pressure => cooler sublimation

• Easy to operate touch screen controls that allow the operator to see what is going on in the process.

• Easy cleaning and certifications by inspection agencies.

• Remote monitoring and servicing from your cell phone or tablet.

• The result is a significant boost to your bottom line and consumer satisfaction.

The traditional weak links in equipment durability have been fully addressed to ensure a quality system that will run 24/7.

HC4: 4 carts, approximately 400 lbs. (180 kgs) wet weight capacity with 2 “shelving spacing

HC7: 7 carts, approximately 700 lbs. (300kgs) wet weight capacity with 2“shelving spacing

HC10: 10 carts, approximately 1,000 lbs. (450kgs) wet weight capacity with 2 “shelving spacing

PITFALLS OF TRADITIONAL DRYING & CURING

1. Takes Weeks or Months to Complete

2. More of an Art than a Science

3. Risk of Mold & Bud Rot

4. Development of CBN & Delta 9

5. Waste of Valuable Resources

(Space, Heating & Cooling, Dehumidification, Human Resources)

FEATURES AND BENEFITS OF CRYO CURING:

1. Better Visual Appeal

2. Higher Retail Value

3. Prevents Mold

4. Increased Extraction Yields

5. Extended Shelf Life

6. Stabilizes Flower

7. Helps Prevent Degradation

WHY CRYO CURE AND NOT A TRADITIONAL FREEZE DRYER?

We can tell you, there are huge differences between a traditional freeze dryer and cryo cure:

- First of all, it is the norm that usually freeze dryers are designed to remove all of the moisture from whatever it is drying. So cannabis comes out dry as dust, without the right moisture content, and you have pulled off a lot of the terpenes as well.

- Also with some freeze dryers the ice bank capacity is not large enough for cannabis, because it has a lot of water, so when your ice bank gets too full, water is not conducted in that chamber anymore and it gets pulled through straight to your vacuum pump, which destroys it very quickly.

- Very importantly, a lot of people who sell freeze dryers, since they don’t usually understand the process, they’ll advise clients to re-hydrate the cannabis, even when is too dry, to go ahead and re-hydrate it, which is not ideal.

- With purchasing a Cryo Cure machine that is a little more expensive than a traditional freeze dryer, by the time you manage to figure out, (if you actually figure it out) experimenting with a couple of loads on a freeze dryer, the money you’ve lost with that cannabis, more than pays for the premium of buying the cryo cure machine, which is ready to go from the first load you put into the machine (no experimenting needed).

IN SUMMARY:

– Traditional methods often leads to dried outcannabis that needs re-hydrated

– Over dried cannabis has a similar consistency of a Cheeto and often turns to dust when pressed

– Often plant degradation occurs which leads to loss of terpenes

– Freeze drying foods is not the same as freeze drying cannabis

– Other machines can be cumbersome & hard to dial in

– Lack of ice bank capacity

– Poor customer service is frustrating

– Other machines breakdown often & can be costly to fix.

WITH CRYO CURE:

– NO NEED TO REHYDRATE CYRO CURED FLOWER!

– Patented “recipe” to retain optimal moisture content (10-12%) in finished flower

– Preserves all terpenes & fragile mono terpenes,even when drying for extraction

– Only freeze dryers built specifically for cannabis & hemp

– Unique features & flower safety assurances built in

– Superior ice bank capacity

– Excellent customer service 24/7

– Cyro Cure machines are low maintenance, easy to use & can be used daily with peace of mind

So the answer is yes! Cryo Cure is the way to go!

Our high-capacity models are designed with features that help speed up processing time without affecting product quality. Upgraded refrigeration capacity contributes to overall faster processing time, while quick condenser defrosting helps ready the machines for a new batch quickly. The programming interface can be monitored remotely on your phone or tablet, while the easy to operate touch screen controls display precisely what’s going on at each stage of the patented Cryo Cure process. These machines are also designed with the ability to load and unload product while the machine is processing another batch. The result is improved efficiency and a lightning-fast return on your investment

- Comes in three sizes: HC4, HC7, and HC10

- Shorter cycle times supported by refrigeration capacity

- Includes proprietary recipes for smokable flower, extraction, and terpene harvesting

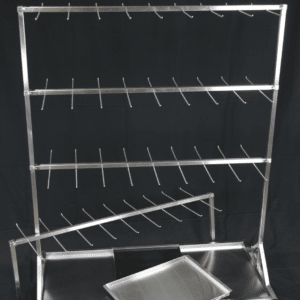

- Easy-to-sterilize racks embedded with zoned temperature monitoring system