CRYO CURE HC PILOT DRYING MACHINE – FOR MEDICINAL CANNABIS

Dry and Cure Cannabis In As Little As 12 – 24 Hours

INDISPUTABLE THC, TERPENE, TRICHOME AND FLAVOR PRESERVATION

Top Quality at a Fraction of the Time

Trichomes do not warp, shrink or break in the Cryo Cure cannabis machine. The final flower has an awe-inspiring look and feel. The aroma is powerful and the flavor is unforgettable, thanks to the high levels of retained terpenes.

PRESET RECIPES FOR SMOKABLE HEMP AND CANNABIS FLOWER

When you work with Cryo Cure’s patented technology, you get the perfected recipes that ensure flower comes out of the machine ready to use with each run. There’s no reinventing the wheel or experimenting with your own harvest: We’ve done all the fine-tuning for you. Multiple settings support whatever you plan to do with Cryo Cure, whether you plan to sell the flower as a smokable product or extract phytocannabinoids and terpenes.

INCREASE CANNABIS AND HEMP EXTRACTION YIELDS

With our pre-programmed Cryo Cure “processing” setting, moisture levels in flower and trim can be quickly reduced to between 1 and 2 percent. This results in significantly higher yields for BHO, DHO, CO2 and ethanol extraction methods; plus, solvent-free extracted and infused products have an improved terpene and cannabinoid profile.

PERFECT MOISTURE CONTENT MINIMIZED MOLD AND MILDEW

Cryo Cure’s precisely-controlled moisture levels prevent oxidation and prohibits the growth of harvest-ruining mold and mildew, while also preventing the spread of bud rot after harvest. Our machines don’t completely eliminate moisture; instead, they use the right balance of time, temperature, and pressure to bring moisture to optimal levels. These settings cure smokable hemp and cannabis flower to a target moisture content of 8% to 12%. For extraction, the moisture content is lowered for maximum results.

Cryo Cure’s patented technologies and methodologies are to eliminate the human error that can occur during the cannabis curing and drying process. The machines are pre-programmed for low moisture content while preserving the terpenes and trichomes.

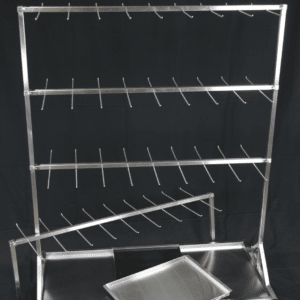

THE HC PILOT: 9 trays, approximately 30 lbs (13KGS). wet weight capacity with 2” shelf spacing.

PITFALLS OF TRADITIONAL DRYING & CURING

1. Takes Weeks or Months to Complete

2. More of an Art than a Science

3. Risk of Mold & Bud Rot

4. Development of CBN & Delta 9

5. Waste of Valuable Resources

(Space, Heating & Cooling, Dehumidification, Human Resources)

FEATURES AND BENEFITS OF CRYO CURING:

1. Better Visual Appeal

2. Higher Retail Value

3. Prevents Mold

4. Increased Extraction Yields

5. Extended Shelf Life

6. Stabilizes Flower

7. Helps Prevent Degradation

WHY CRYO CURE AND NOT A TRADITIONAL FREEZE DRYER?

We can tell you, there are huge differences between a traditional freeze dryer and cryo cure:

- First of all, it is the norm that usually freeze dryers are designed to remove all of the moisture from whatever it is drying. So cannabis comes out dry as dust, without the right moisture content, and you have pulled off a lot of the terpenes as well.

- Also with some freeze dryers the ice bank capacity is not large enough for cannabis, because it has a lot of water, so when your ice bank gets too full, water is not conducted in that chamber anymore and it gets pulled through straight to your vacuum pump, which destroys it very quickly.

- Very importantly, a lot of people who sell freeze dryers, since they don’t usually understand the process, they’ll advise clients to re-hydrate the cannabis, even when is too dry, to go ahead and re-hydrate it, which is not ideal.

- With purchasing a Cryo Cure machine that is a little more expensive than a traditional freeze dryer, by the time you manage to figure out, (if you actually figure it out) experimenting with a couple of loads on a freeze dryer, the money you’ve lost with that cannabis, more than pays for the premium of buying the cryo cure machine, which is ready to go from the first load you put into the machine (no experimenting needed).

IN SUMMARY:

– Traditional methods often leads to dried outcannabis that needs re-hydrated

– Over dried cannabis has a similar consistency of a Cheeto and often turns to dust when pressed

– Often plant degradation occurs which leads to loss of terpenes

– Freeze drying foods is not the same as freeze drying cannabis

– Other machines can be cumbersome & hard to dial in

– Lack of ice bank capacity

– Poor customer service is frustrating

– Other machines breakdown often & can be costly to fix.

WITH CRYO CURE:

– NO NEED TO REHYDRATE CYRO CURED FLOWER!

– Patented “recipe” to retain optimal moisture content (10-12%) in finished flower

– Preserves all terpenes & fragile mono terpenes,even when drying for extraction

– Only freeze dryers built specifically for cannabis & hemp

– Unique features & flower safety assurances built in

– Superior ice bank capacity

– Excellent customer service 24/7

– Cyro Cure machines are low maintenance, easy to use & can be used daily with peace of mind

So the answer is yes! Cryo Cure is the way to go!

- 12 to 15 hour cycle time, depending upon product density and selected setting

- Smaller footprint than other Cryo Cure models

- Six built-in drawers

- Drawer size: Approx. 33.4” by 13.7”

- Comes equipped with three proprietary and patented Cryo Cure recipes

- Customize your settings through built-in controls

- Up to 9 kg wet weigh-in per cycle