The Original Resinator XLS PRO

The Original Resinator XLS Pro – 3-in-1 Commercial Post-Harvest Powerhouse

Trim. Sift. Extract. All in one machine.

Hypercompetitive cannabis and hemp markets demand innovative solutions. The new all stainless steel XLS Pro radically increases your lab’s ability to make both hydrocarbon-based and solventless SKUs for less, plus it’s the sharpest tool there is for performing fresh frozen trimming to make live dried flower. Contact us to learn more about how the XLS Pro can revolutionize your operation today.

The Original Resinator XLS Pro is the ultimate all-in-one post-harvest solution for cannabis and hemp professionals. Designed for high-volume, premium-quality processing, it combines precision trimming, solventless extraction, and hydrocarbon-ready preparation in a single piece of equipment—saving you space, time, and operating costs.

Key Functions

-

Precision Trimming

-

Handles both dry and fresh frozen flower.

-

Removes excess leaves without damaging trichomes.

-

Delivers a clean, uniform finish.

-

-

Solventless Extraction

-

Uses cold temperatures and agitation to separate trichomes into kief, dry sift, or hash.

-

Preserves terpene profile and product quality.

-

-

Hydrocarbon-Ready Preparation

-

Prepares flowers for BHO or other hydrocarbon extraction.

-

Removes unwanted plant matter, reducing solvent use, improving purity, and boosting yields.

-

Why Choose the XLS Pro?

-

Maximize Yield & Purity – More trichomes, less waste, better concentrates.

-

Reduce Solvent Costs – Cleaner input means less solvent required.

-

Save Time & Space – One machine replaces three separate systems.

-

Preserve Terpenes – Cold processing locks in aroma and flavor.

Ideal For:

-

Licensed producers

-

Extraction labs

-

Large-scale cultivation facilities

-

Hybrid operations running both solventless and hydrocarbon extractions

In short: The XLS Pro is not a butane extractor—but it’s the perfect pre-processing step for any high-quality extraction workflow. Whether you’re producing premium solventless concentrates or prepping for BHO, this machine ensures your material is clean, uniform, and extraction-ready.

BENEFITS:

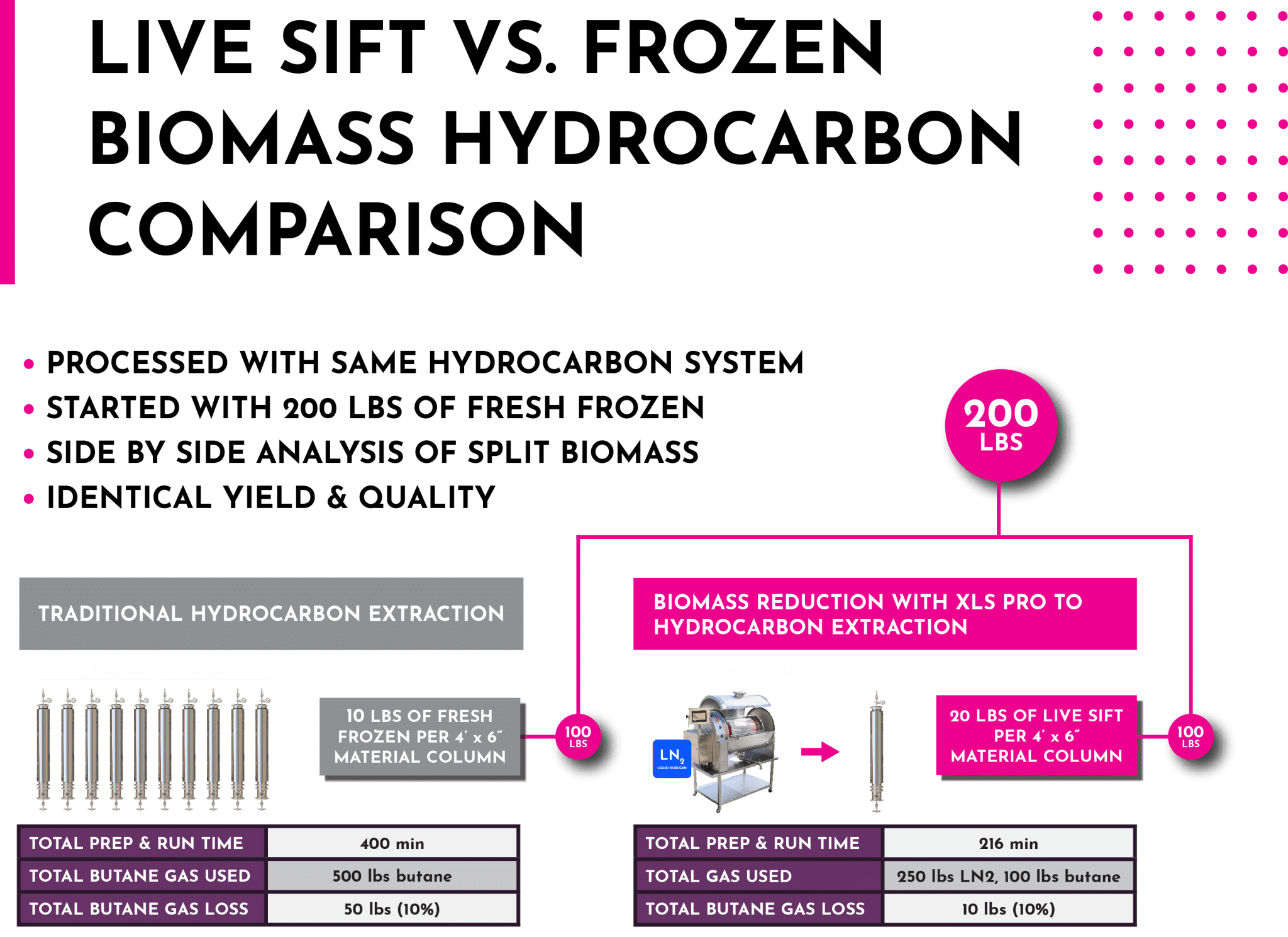

- INCREASE YOUR HYDROCARBON PROCESSING EFFICIENCY BY UP TO 85%

- GO WATERLESS FOR SOLVENTLESS & DOUBLE YOUR LIVE ROSIN THROUGHPUT WITH NITRO-SIFT™

- CRYO-TRIM® YOUR LIVE, FRESH FROZEN & CURED FLOWERS WITH NO BLADES

- BLAST TWICE AS FAST WITH HALF THE GAS

- PREMIUM LIVE SOLVENTLESS WITH NO WATER OR PLUMBING

- CROP-TO-CURE® IN 48 HOURS AT SCALE

- DATA-BACKED GAME CHANGING LIQUID NITROGEN TECHNOLOGY

- PROUDLY MADE IN USA FROM PREMIUM COMPONENTS

The XLS Pro is not a butane extractor, but it is the ideal “pre-processing” step for that type of extraction.

Because if you load material directly into a butane extractor, you’re carrying a lot of extra plant matter that:

-

Takes up space in the extractor (less productive material per cycle).

-

Contaminates the concentrate with chlorophyll and plant waxes.

-

Consumes more butane because more solvent is needed to extract the desired compounds.

-

Reduces purity and flavor by pulling in unwanted elements.

What the Resinator XLS Pro does:

-

Removes excess leaves and parts that don’t contribute to quality.

-

Separates intact trichomes before chemical extraction.

-

Leaves only the best of the flower, so that in the butane extractor you get more resin, more terpenes, and fewer impurities, using less solvent and less time.

In other words, it prepares the material so the butane works less and the end result is better.

The XLS Pro is basically a 3-in-1 in cannabis/hemp post-harvest:

-

Trimming → Trims flowers (dry or fresh frozen) removing leaves without damaging trichomes.

-

Solventless extraction → Uses cold and agitation to separate trichomes as kief/dry sift or hash.

-

Preparation for solvent extraction (BHO) → Leaves flowers clean, uniform, and ready to go into a butane or similar extractor, optimizing yield and purity.

In one machine, you do what would normally require three separate pieces of equipment—saving space, time, and money.