HEMP PROCESSING LINE

PROCESSING LINE FOR PROCESSING OF INDUSTRIAL HEMP

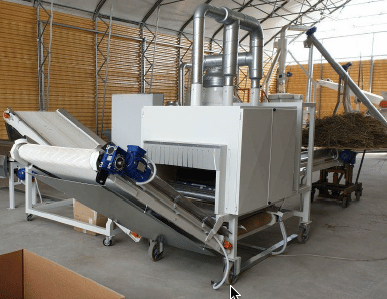

Industrial hemp separating machine – 3 phases of separation

Designed for separation of inflorescence of the hemp plant from the rest of the stem of the plant.

Dry processing material is dosed onto input conveyor of the machine. In the separator, the flowers, seeds and leaves are separated from the stem. The machine has a filter for collecting the hemp dust created due to the separation inside of the machine.

After the separation, the mixed mass of separated flowers, seeds and leaves go out on one outlet, and the stems go out on another.

Power: 3,2 kW

Voltage: 400 V, 50 Hz – 3 meter cable length from the el. cabinet and 5-pin 16A industrial plug

Material: Construction, sheeting – carbon steel, painted in primary and final color RAL 9002

Sides of conveyor, hopper – INOX AISI 304

Belt, cleats – white (FDA norm)

Brush – polyamide

Hemp flower separator – 2nd step

The hemp flower separator is designed for separation of leaves and flowers ,from the seeds. Processing material, with dosing conveyor, is dosed into the hopper on top sheet of the separator form where it enters into the sieve. Inside of the sieve is formed mechanical separation of leaves and flowers from the seed, with rotation of the brushes and thus processing material is cut on pieces defined with mesh openings.

On the back side of the separator, behind the perforated part of the sieve or mesh sieve openings of the sieve, there is an outlet for separated parts of the stalk (and seed).

Under the sieve there is an outlet for separated parts of the leaf and flowers.

– power: 1,5 kW

Dimensions: Length: 2800 mm

Height: 3070 mm

Width: 1530 mm

Material: Construction, sheeting – carbon steel, painted in primary and final color RAL 9002

Sieve, hopper, inside of rebler which is in contact with the processing material – INOX AISI 304

Brushes – Polyamide

SUMMARY

In summary, the Hemp Processing line allows you to input the full stalks with the leaves, flowers, and seeds, leaving the final outputs as the separated:

- Stalks

- Flowers & leaves grinded

- Seeds

- From this point onwards the dried grinded flowers and leaves are ready to be put into an extraction system, like a Supercritical Co2 extraction machine for example.

- The stalks will be ready to be processed into machinery for fibre extraction.

- And the separated hemp seeds will be collected in a bag, ready for its intended commercial use.